The ignition system is mainly used to ignite the pilot burner to prepare for the ignition start control of various burners. According to user requirements, it can realize the single-step operation of the equipment, program-controlled automatic operation, fuel output adjustment, etc.

The ignition system consists of a high-energy explosion-proof ignition device, a pneumatic explosion-proof propulsion device, an ignition flashlight, an ignition quick-break valve, a flame detector, a cooling air system, and an ignition explosion-proof control cabinet.

The high-energy ignition device is mainly composed of three parts: high-energy explosion-proof igniter NIE-6B, high-energy explosion-proof semiconductor igniter NIG-1, and high-voltage shielded cable NIL-6000.

The working principle of the high-energy explosion-proof ignition device is: AC power frequency 220VAC, which is converted into DC pulse voltage by boosting rectification, and charging the energy storage capacitor. When the voltage on the capacitor rises to the breakdown voltage of the discharge tube, the discharge current flows through the discharge tube, choke coil, and shielded cable until a high-energy arc spark is formed in the gap between the semiconductor electric nozzles. When the igniter stops working, the remaining charge on the capacitor is grounded through the bleeder resistor.

The shell of the high-energy igniter is a metal shell, with a smooth and beautiful appearance, good tightness, and an explosion-proof grade of BT4. The igniter can fire continuously for up to 5 hours. The discharge voltage is low, the ignition energy is large, the single ignition energy is 6 J, and the spark frequency is 10-15 times/sec. It has a strong ability to adapt to the environment, the working temperature range is -30℃~85℃, and the relative humidity is less than 95%.

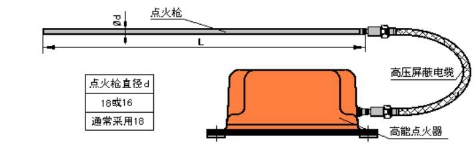

The semiconductor electric nozzle of the ignition gun is a patented product of NBE, with low discharge voltage and arc starting voltage <1000V. The semiconductor electric nozzle has a long service life and can be fired 200,000 times. The igniter head and the gun body are made of high-quality stainless steel, which can withstand higher temperatures without being burnt. It can be used for a long time in an environment below 1000°C, and can withstand high temperatures of 1400°C in a short time. The resistance value of the center circuit of the ignition gun is <0.05Ω, and the anti-electric strength is DC8000V. The length of the ignition gun is determined according to the specific project, and shall meet the needs of burner ignition.

The high-voltage ignition shielded cable is used to send the current output from the igniter to the semiconductor nozzle of the igniter for discharge. The connectors at both ends of the cable are made of special stainless steel, which are tightly connected with the output port of the igniter and the bottom of the igniter. The resistance of the center circuit is less than 0.02Ω, which ensures the safety and reliability when working with large currents. The main part of the cable is protected by a metal hose, with an electrical resistance of DC4000V, and a minimum bending radius of 64mm. The working environment temperature of the ignition cable is -30℃~110℃. The length can meet the requirements of the forward and backward of the ignition gun and the installation position.

Shandong Yaoshun Thermal Energy Technology Co., Ltd.

50T/H Natural Gas Ignition System for Three Wastes Furnace

Taiyuan Boiler Group Power Engineering Co., Ltd.

130T/H coal-fired steam injection boiler complete equipment natural gas ignition system

Shanxi Lantian Environmental Protection Equipment Co., Ltd.

Under-bed ignition system

Hebei China Coal Risun Coking Co., Ltd.

Automatic ignition system for crude benzene tube furnace

Inner Mongolia Qinghua Tengri Fine Chemicals Branch

Circulating fluidized bed boiler ignition system